Diesel Injection Pump Rebuilds

Know what’s wrong BEFORE teardown!

We’ll help you diagnose before you remove the pump… AND we’ll tell you what’s wrong with your pump BEFORE we tear it down.

About us

Accurate Diagnosis Comes First!

Most of our work focuses on older diesel equipment—farm tractors, semis, and diesel cars and trucks that still rely on mechanical fuel systems.

We believe fuel system problems should never be guessed. The injection pump represents nearly 50% of the entire injection system, which is why proper diagnosis is critical before any teardown or rebuild work begins.

Our approach is simple: identify the real problem, explain it clearly, and rebuild only what actually needs to be rebuilt.

Years in Business

Vehicles Serviced

Certified Technicians

Services

Diesel Injection Pump, Injector & Turbo Rebuild Services

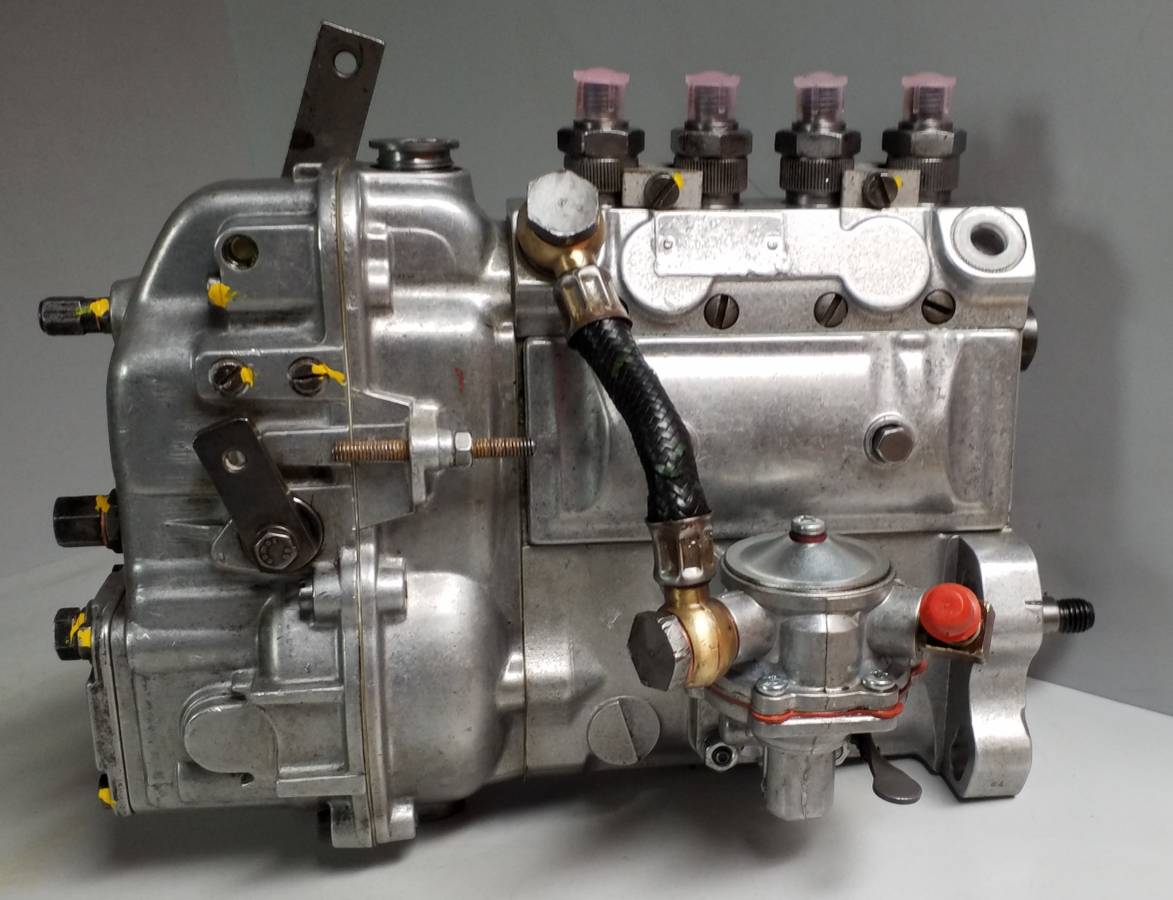

Diesel Injection Pumps

We rebuild diesel injection pumps for older agricultural equipment, farm tractors, semis, and diesel cars and trucks.

Diagnosis is done before teardown so you know exactly what you’re dealing with.

On-the-Shelf Parts & Rebuild Capability

We maintain an extensive on-hand parts inventory for the most commonly used components in our rebuilds. This allows us to complete repairs efficiently and get your equipment back up and running as quickly as possible.

That said, due to recent supply chain challenges and shipping changes, some parts are becoming harder to source. Availability may vary, and we’ll always be upfront about timelines.

100%

Customer Satisfaction

Brands & Systems We Service

Diesel Injection Pump, Injector & Turbo Rebuild and Repair For…

John Deere, Case/IH, Ford, Ferguson, Massey, White/Oliver, David Brown, Cummins, and more.

Bosch VA, VE, Delphi, Caterpillar, Lucas CAV, Mercedes, Roosa Master, Stanadyne, Simms, Zexel, Zetor, Belarus, McCormick, Mahindra, Kubota, Deutz, AGCO Allis, Yanmar, Landini, Powertrac, Lamborghini, Mitsubishi, Power-Trac Loader.

Why Customers Choose Us

Customers choose us because we diagnose the problem before teardown, explain what’s wrong clearly, and rebuild only what actually needs to be rebuilt.

Pre-Removal Diagnosis

Central Kentucky Diesel Rebuild Facility

Professional Test Equipment

On-the-Shelf Parts Inventory

Injector Rebuilds Available

Fuel Contamination: Bacteria & Algae Warning

Look,There are NO additives that will get rid of bacteria, algae, or water!! Some claim to kill the bacteria … We have not seen proof. Maybe so, but if you kill a mouse is it still there?

And so it is, if the algae and bacteria are killed it is still there at the bottom of the tank only to be taken up through the fuel pickup line.

The tank MUST be cleaned out to remove all contamination. Call for more information.

Warning - 1

Bacteria & Algae Warning

We are seeing more fuel contamination than ever before.

-

Bacteria appears as rust-colored material in the tank and fuel system.

-

Algae shows up as black particles in the tank.

If contamination is present in the injection pump, it is also in the tank and throughout the entire fuel delivery system.

Warning - 2

Critical Engine Safety Notice

Always pull the dipstick and check your crankcase oil level.

A leaking seal in a rotary injection pump or a failing mechanical lift pump can cause fuel to enter the crankcase. This may overfill the engine oil and lead to engine runaway, which can cause severe engine damage.

Warning - 3

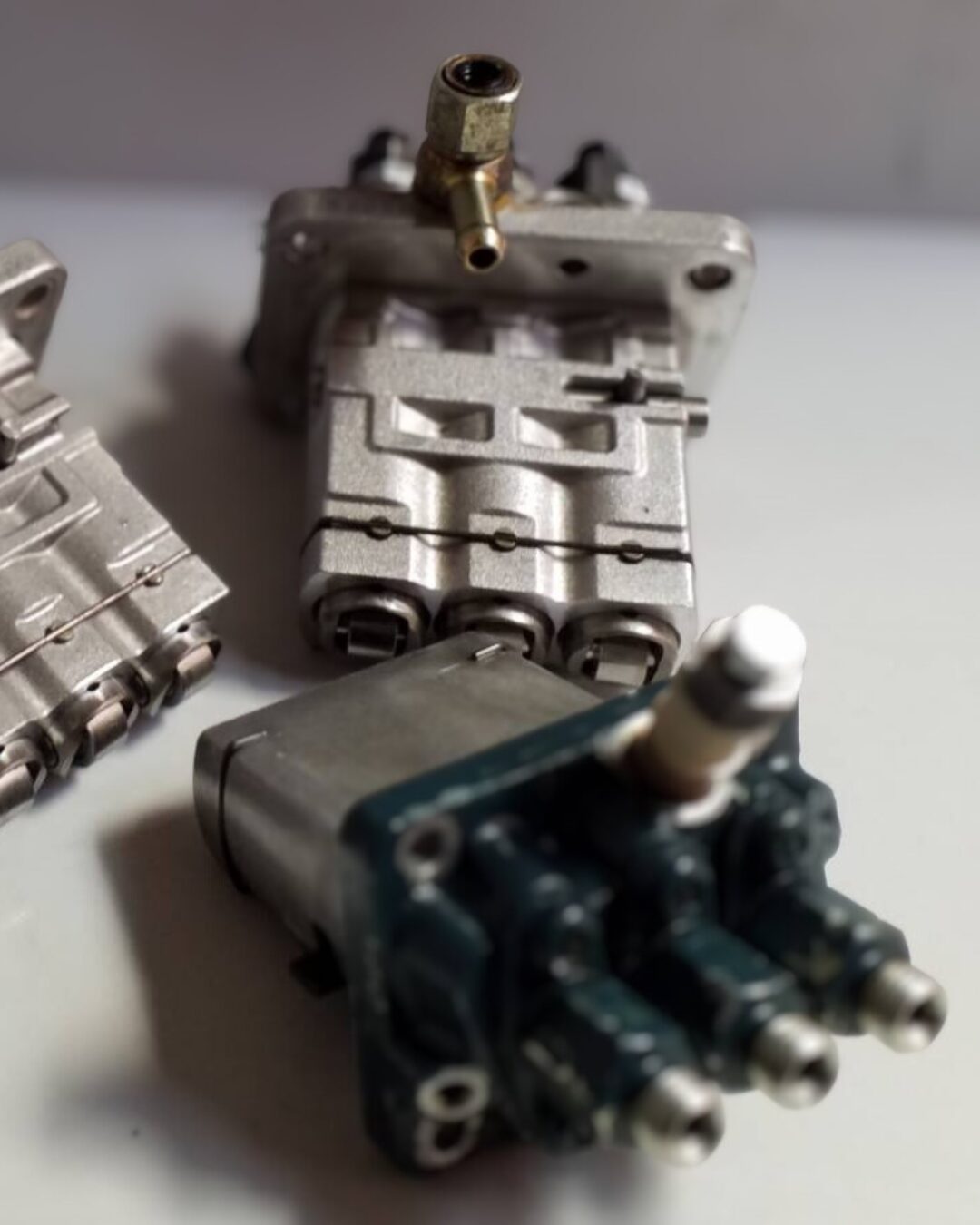

Professional Rebuild & Test Equipment

Rebuilding without verified testing leads to repeat failures, poor performance, and shortened component life.

All pumps are rebuilt in our Kentucky facility using professional-grade test equipment, including:

-

MakTest – Common Rail injector testing

-

Hartridge 450 & 875 – Rotary pumps

-

Hartridge 1100 – Inline pumps

-

Bacharach Specialist 10

Need Help With a Diesel Fuel System Issue?

Use the form below or call us to discuss the issue. You’ll speak directly with someone who works on diesel fuel systems every day — no call centers, no guessing, just clear answers before teardown.